5-axis machining

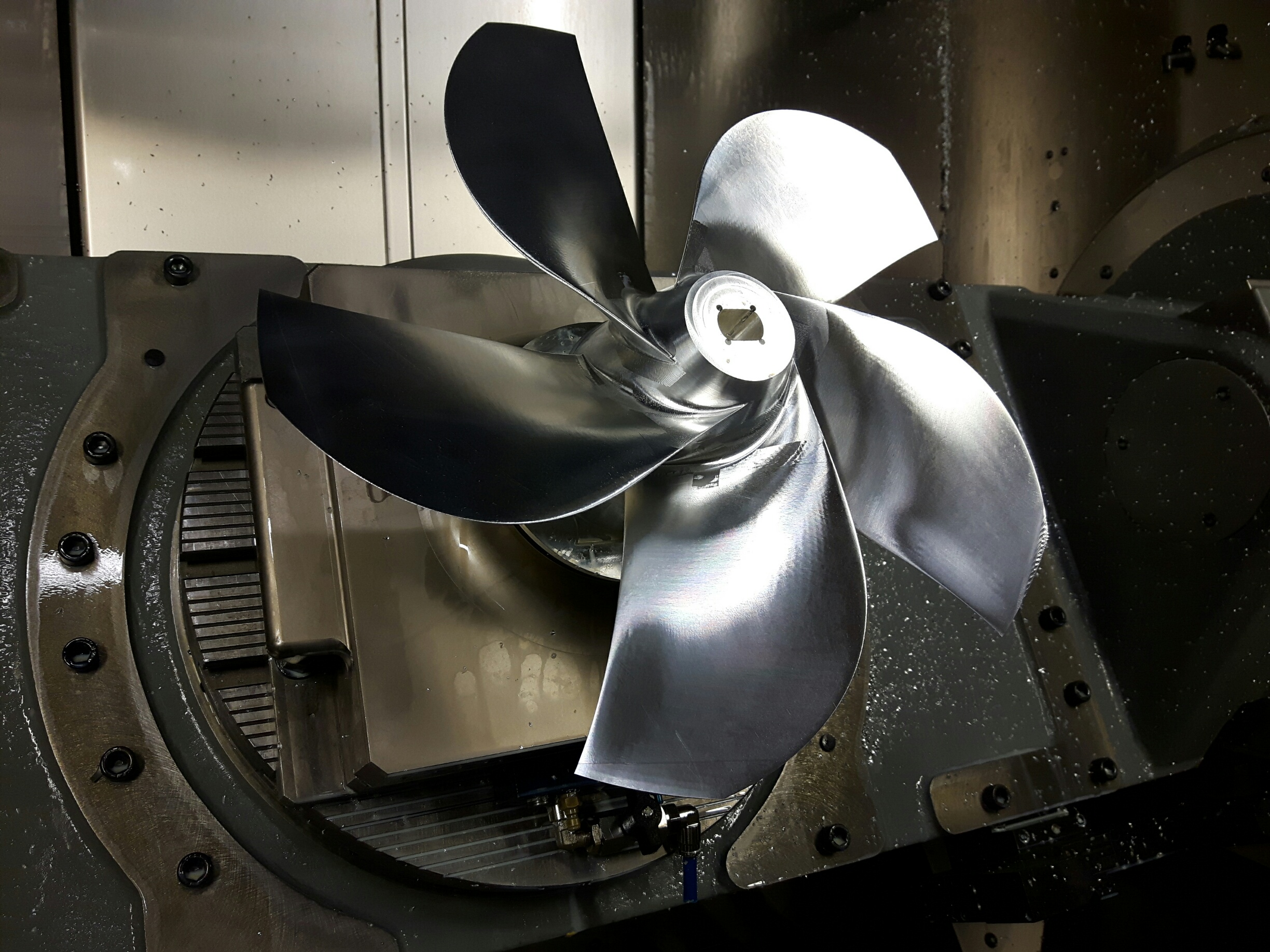

Machining is performed mainly using our state-of-the-art 5-axis CNC machines.

5-axis machining technology is geared to complex geometries such as turbine blades and impellers, but also to milling of simpler cast pieces.

Typical materials in small and pre-production batches are steel, stainless steel, aluminium, grey cast iron, ductile iron and brass, together with various plastics.

Our advanced plant is under continuous development and is specialised for making moulds, models, tools, fixtures, prototypes and other components.

We have capacity and expertise for machining both small complex and large parts with high precision. Batch runs may vary between 1 and around 1,000 parts.

For higher-volumes, we offer automated production in our robotic cells with unmanned manufacturing of complex parts 24/7.